PRODUCT

PRODUCT

MPP Power Cable Proteciton Pipe

The modified polypropylene MPP power cable protection pipe is commonly used in a construction project for laying pipelines and cables under roads, railways, buildings, river beds and other special sections without massive dredging and damaging the road surface. Compared with the traditional trenching method, trenchless project is more suitable for the current environmental protection requirements.

Key word:

Category:

Plastic Pipe Class

Hotline:

MPP Power Cable Proteciton Pipe

Picture and text details

Product Introduction

The modified polypropylene MPP power cable protection pipe is commonly used in a construction project for laying pipelines and cables under roads, railways, buildings, river beds and other special sections without massive dredging and damaging the road surface. Compared with the traditional trenching method, trenchless project is more suitable for the current environmental protection requirements. This technology can also be used to lay pipelines in areas where excavation cannot be carried out.Such as monument protection zone, downtown area, crop and farmland protection zone, highway, river, etc. MPP etc. can be widely used in municipal, telecommunication, electric power, gas, water, heat and other pipeline projects.

Modified polypropylene (MPP pipe) power cable protection casing has the characteristics of high temperature resistance and external pressure resistance, and is suitable for high voltage transmission wire and cable row pipe above 10KV. The common specifications of the pipe are 110 - -250mm, divided into ordinary type and reinforced type. Ordinary MPP pipe is suitable for excavation and laying construction and non-working excavation through the construction of burial depth of less than 4m; strengthening type is suitable for non-excavation through the construction of burial depth of more than 4m project.

Products Features

1. High rigidity and hardness

When the temperature reaches 100 ℃, the pipe still maintains high rigidity and hardness, and will not be deformed, flattened or punctured by sharp objects.

2. High tensile and bending strength

In trenchless pipe dragging process, the pipe will not be stretched, deformed or bent.

3. Reliable connectivity

Simple welding process; The unique hot-melt butt welding technology makes the strength of the interface higher than that of the pipe body, ensures the safety and reliability of the interface.

4. Excellent corrosion resistance

Except for a few oxidants, it can resist the corrosion of various chemical media, no electrochemical corrosion, more than 50 years working life.

5. Cold resistance

No embrittlement even under -20oC, suitable for cold area.

6. Low friction coefficient

Smooth inner wall will not scratch the surface of the cable, has superior wear resistance.

7. Excellent electrical insulation

8. Long term use temperature -40℃-+45℃

Application of MPP Pipe

1. City and countryside trenchless horizontal directional drilling cable pipe laying project and open excavation cable pipe laying project;

2. City and countryside trenchless horizontal directional drainage and pipe laying project.

3. Industrial waste water discharge project

Construction Instructions

1. the pipe transport, construction process is strictly prohibited arbitrary throwing, impact, scratching, exposure to the sun.

2. hot fusion butt when the two pipe axis to align, end cutting to vertical flat.

3. processing temperature, time, pressure, depending on the weather conditions to adjust accordingly. 4.

4. MPP pipe minimum bending radius should be ≥ 75 times the outer diameter of the pipe.

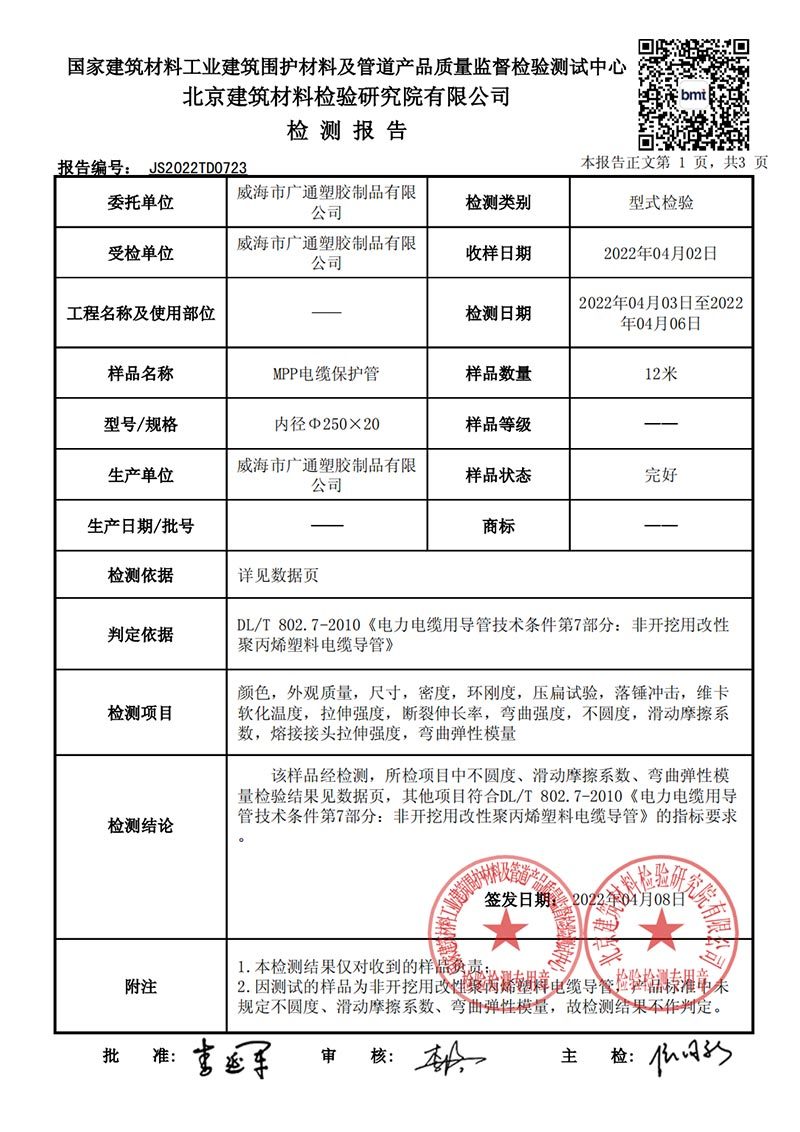

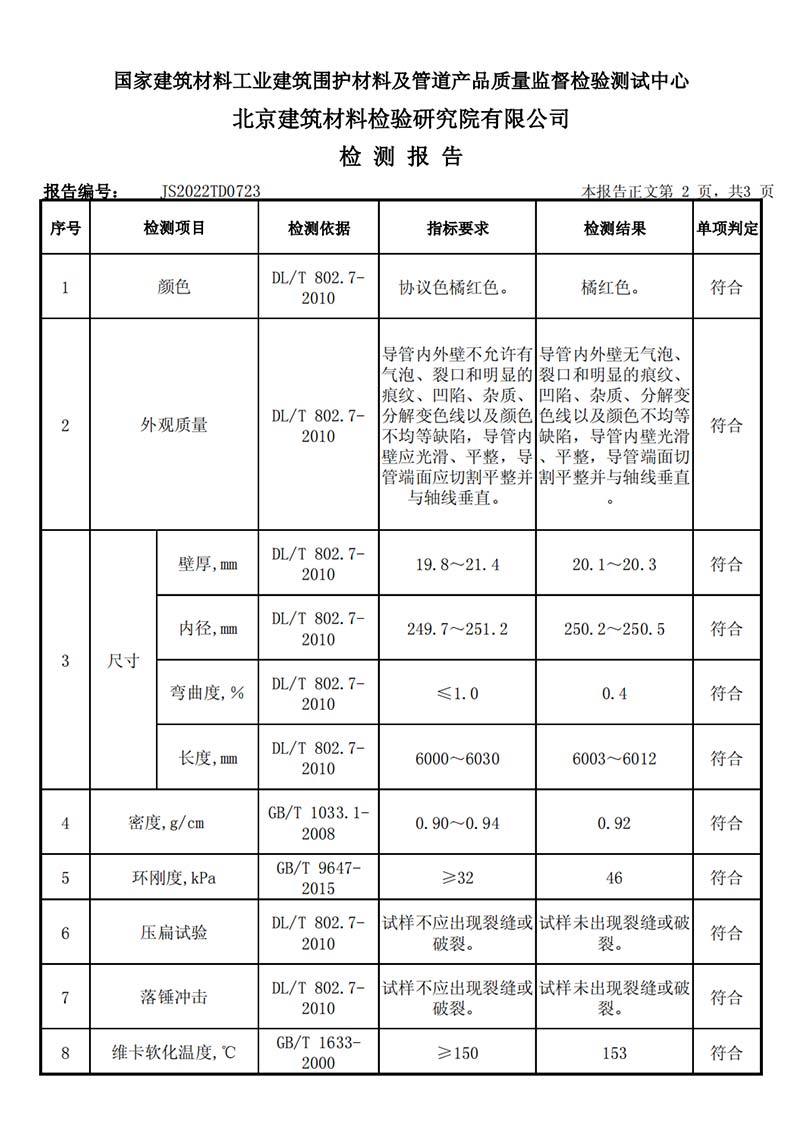

Technical index of MPP cable pipe

|

Physical and mechanical properties |

PE |

MPP |

|

Tensile strength of pipe and welded joint |

18 |

≥24 |

|

Hot compression of Ring Piece (70℃,2h) kN |

1.3 |

≥2.0 |

|

bending strength |

16.5 |

≥37 |

|

Bending elastic modulus |

700~750 |

≥900 |

|

Drop impact test(-5℃,8h) |

Unbroken |

Unbroken |

| Vicat heat resistant(1kg,50℃/h) |

110 |

150 |

|

Note: The pipe specification is 180 * 12.0 |

||

|

Item |

index |

|

|

Density g/cm³ |

0.90~0.94 | |

| Sliding friction coefficient | <0.35 | |

| Vicat heat resistant (10N,50oC/h),℃ | ≥120 | |

|

Drop impact test (-5 ℃/8h,r20) |

φ>160,10kgx2m | 9/10 unbroken |

| φ≤160,5kgx2m | ||

| φ≤160,6kgx2m | ||

|

Tensile strength, MPa |

23±2℃ | ≥24.0 |

| 70±2℃ | ≥18 | |

|

Tensile strength of hot melt joint (23±2℃), MPa |

≥21.6 | |

|

Flattening test (1/2) |

23±2℃ |

No broken |

| -5 ℃/8h | ||

|

Bending strength(23±2℃), MPa |

≥37.0 | |

|

Bending elastic modulus, MPa |

900~1200 | |

|

Ring Piece hot compression force (70℃/2h,5%),KN |

≥1.3 | |

Specification of MPP cable pipe

Previous page

Next page

Next page

HPVC Double wall Corrugated Pipe

Next page

Recommended products

Prepare for your choice