PRODUCT

PRODUCT

Modified Raw Materials

The development of this modified raw material has solved the problem that many MPP cable protection pipe enterprises' formula products cannot meet the standard, and simplified the production process, saving production time and improving production efficiency.

Key word:

Category:

Plastic Pipe Class

Hotline:

Modified Raw Materials

Picture and text details

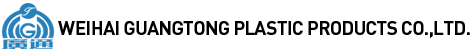

Pictures

| Before raw material modification | After modification of raw materials | Finished Product Pipe |

|

|

|

|

Product description

The raw material is developed by Weihai Guangtong Plastic Products Co., Ltd (a paper proof enterprise of the State Grid) jointly with Beijing University of Chemical Technology, open the bag and use, without adding color masterbatch, directly produce the finished product, the quality of the national grid standard requirements.

The development of this modified raw material solves the problem that many MPP cable protection pipe enterprises' formula products can not meet the standard, while simplifying the production process, saving production time and improving production efficiency.

Ltd. can provide customers with a free 20-30 cm sample tube to do performance testing, while providing experimental pipe at low prices, after meeting the standard, the two sides then discuss the demand for modified material quantity and price. The modified material is divided into thin-walled, medium-walled and thick-walled materials. We guarantee the quality and delivery on delivery.

Welcome to contact us, and we look forward to cooperating with you successfully.

Technical specifications

Technical performance

The technical performance of the conduit should be in accordance with the provisions of Table 2.

Table 2 Technical Performance

| Item | Unit | Technical performance indicators | |

| Density | g/cm³ | 0.90~0.94 | |

| Ring stiffness(3%)(room temperature) | kPa | SN24 grade≥24 SN32 grade≥32 SN40 grade≥40 |

|

| Crush test | Loaded to the specimen vertical deformation of 50% of the original inner diameter, the specimen should not appear cracks or rupture | ||

| Drop hammer impact | According to the test in Table 3, the specimen should not have cracks or ruptures | ||

| Vicat softening temperature | ℃ | ≥150, according to GB/T1633 test (using As method) | |

| Tensile strength | MPa | Pipe: ≥25; fusion joint: ≥22.5 | |

| Elongation at break | % | ≥400 | |

| Bending strength | MPa | ≥36 | |

Table 3 Drop hammer impact test

| Nominal internal diameter mm | Drop weight (1.0% deviation from soil) kg | Impact height (deviation ±20) mm | |

| 100 | 6.0 | 200 | |

| 125 | 7.5 | ||

| 150 | 10.0 | ||

| 175 | 10.0 | ||

| 200 | 12.5 | ||

| 225 | 12.5 | ||

| 250 | 15.0 | ||

| Note 1: The specimen is insulated at a temperature of (-5±1)℃ for at least 8h before the test. Note 2: The radius of curvature of the spherical surface of the falling hammer head is 50 mm, and the diameter of the punch column is 90 mm. |

|||

Other requirements

In addition to meeting the above technical performance requirements, the catheter should also meet other non-general technical requirements such as thermal oxygen stability. In addition to the above technical performance requirements, in the user has special requirements or under special conditions, should also meet other non-general technical requirements, such as thermal and oxygen stability, etc., the thermal and oxygen stability of the catheter requirements see Appendix B.

Contact information

Weihai Guangtong Plastic Products Co.

Weihai. Shandong

Contact:Tan Yongzhi Mobile:156 5013 6789

Lv Xinmin Mobile:186 6310 6268

E-mail:whguangtong@163.com Website:www.gtplastic.cn

Previous page

Next page

Next page

nothing

Next page

Prepare for your choice